Grinding Processes Material

Manufacturing Processes 2: Grinding, Honing, .

... material removal manufacturing processes: grinding, ... the following material removal manufacturing processes: ... Manufacturing Processes 2: Grinding, ...

Surface grinding Wikipedia

Surface grinding is the most common of the grinding operations. It is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more refined look by removing the oxide layer and impurities on work piece surfaces.

Alumina Media: HighQuality Grinding Material .

Ask Norstone, Inc. about the right materials for a specific industrial project; For example, alumina media and materials. Consider the vulnerability of the milling machine and equipment, the temperatures to which materials will be exposed, and the pressures that they will be under in grinding, polishing, milling or deburring processes.

Review of Analysis Optimization of Cylindrical Grinding ...

Grinding is the machining processes which improve surface quality and dimensional accuracy of work piece. [1] There are various process parameters of a cylindrical .

Chapter 25 (grinding) SlideShare

1. GRINDING AND OTHER ABRASIVE PROCESSES 1. 2. Material Removal Processes A family of shaping operations, the common feature of which is removal of material from a starting workpart so the remaining part has the desired geometry. Machining – material removal by a sharp cutting tool,, turning, milling, drilling.

Grinding of Glass: The Mechanics of the .

An investigation of the material removal process in grinding glass and the effects of the grinding process on the surface structure and fracture strength of the finished product is reported in two papers.

Grinding Process, Finish Machining, Aerospace .

Grinding Roughs Out a New Niche ... The coolant helps keep the work piece and grinding wheel cool so the material being ... These grinding processes are also ...

CHAPTER 1 INTRODUCTION TO GRINDING

grinding processes. Grinding is the most common form of abrasive machining. It is a material cutting process which engages an abrasive tool whose cutting elements are grains of abrasive material known as grit. These grits are characterized by sharp cutting points, high hot hardness, and chemical stability and wear resistance. The grits are

Milling vs. Grinding for Rapid Stock Removal .

Advanced Manufacturing Media is a leading source for ... Milling vs. Grinding for Rapid Stock Removal. ... grinding processes have been unable to reach high ...

GRINDING MACHINES Carnegie Mellon University

GRINDING MACHINES. Grinding is the process of removing metal by the application. of abrasives which are bonded to form a rotating wheel. When. the moving abrasive particles contact the workpiece, they act. as tiny cutting tools, each particle cutting a tiny chip from the. workpiece.

Precision Creep Feed Grinding | ELE Advanced .

ELE offers creep feed grinding processes, ideal for generating complex forms quickly and efficiently, such as the fir tree root on turbine blades.

How grinding wheel is made material, history, .

Raw Materials Two important components, abrasive grains and bonding materials, make up any grinding wheel. Often, additives are blended to create a wheel with ...

What is the manufacturing process of grinding .

Get an answer for 'What is the manufacturing process of grinding wheels, and what are some of their uses?' and find homework help for other Science questions at eNotes

Unit Operations in Food Processing R. L. Earle

In the grinding process, materials are reduced in size by fracturing them. The mechanism of fracture is not fully understood, but in the process, the material is stressed by the action of mechanical moving parts in the grinding machine and initially the stress is absorbed internally by the material as strain energy.

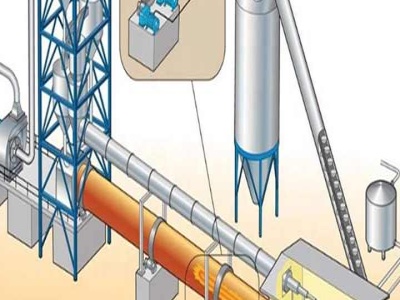

Cement Manufacturing Process | Phases | Flow .

Raw material extraction/ Quarry; Grinding, Proportioning and Blending; Preheater Phase; Kiln Phase; Cooling and Final Grinding; Packing Shipping; Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. .

ABRASIVE AND NONTRADITIONAL PROCESSES

7ABRASIVE AND NONTRADITIONAL PROCESSES CHAPTER CONTENTS Grinding ... Grinding is a material removal process in which abrasive particles arc contained in a bonded ...

Machining Processes | Machining | Grinding .

Machining ProcessesMachining processes work on the principle that the tool is harder than the work piece. Some materials, are too hard or too bri...

TYPES OF GRINDING PROCESS |

Surface grinding process is used for grinding and precise finishing the flat surfaces. Grinding wheel will rotate and workpiece will be feed in horizontal direction, below the grinding wheel, with the help of fed table. Surface .

Materials On The Grinding Process .

cement raw material grinding process – grinding cement raw materials NMN. Cement industry, mining, crushing, raw material, crushing, raw mainly has the following process. mining, cement crushing, raw . chat Online

machining Material Removal Processes

Machining is a term used to describe a variety of material removal processes in which a cutting tool removes unwanted material from a workpiece to produce the desired ...

Abrasive | material |

Abrasive: Abrasive, sharp, hard material used to wear away ... The same basic processes are used in the ... Abrasive grinding wheels are the only means for ...

eFunda: Engineering Processes

Home page for manufacturing processes. Covers hot forming, cold forming, heat treatment etc.

MACHINING PROCESSES AND MACHINE TOOLS .

Traditional machining processes consist of turning, boring, drilling, reaming, threading, milling, shaping, planing, and broaching, as well as abrasive processes such as grinding, ultrasonic machining, lapping, and honing. Advanced processes include electrical and chemical means of material removal, as well as the use of abrasive jets, water jets, laser

Latest Posts

- آلة طحن الكرة المنغنيز

- شراء كسارة ملموسة أستراليا

- تستخدم كسارة الفك sayaji في المملكة العربية السعودية

- للبيع شاكر ذهبي

- مصانع غسيل الفحم في مصر

- سحق خردوات الخرسانة السعودية

- صناعة الرخام معدات

- شاشات مثقبة كسارة الحجر

- ثقوب لآلة طحن

- كليات التعدين الجزائرية

- طحن الكرة من النحاس

- أريد أن أبدأ كسارة الحجر في هيماتشال براديش

- تأثير محطم في أي بلد جعل

- الموردين مطحنة الفحم في مصر

- المعدات المستخدمة في تعدين الذهب

- jaw crusher buyers orissa

- Vibrating Moxibustion

- homedics cenit 600h eu 3d shia masa

- feed mills equipment in south africa

- sand crushing and screening equipments

- sizeof coal conveyor belts

- grinding mineral roller

- granulator machine for sale canada

- grinding mills cachedvibratory

- gold mining equipment and names

- coal mining steps in the form of a flow diagram

- pengenalan mesin grinding

- Sedimentation Coal Siltation

- coal crusher equipment small

- silica sand mining washing plant 038 nbsp