the procedures of processing iron ore

What's the process of iron ore mining? Quora

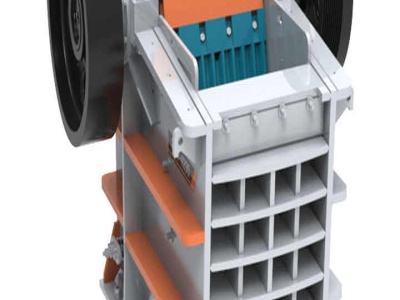

The process of iron ore mining, the first step is first ore is crushed and transported back to the OPFs for grinding and the wet scrubber removes the waste from the ore and categorizes it into oversize, midsize and undersized. In this .

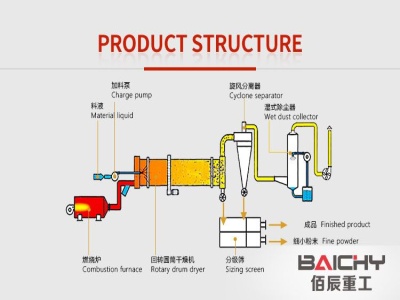

Iron ore pelletizing Metso

Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel.

The Sintering Process of Iron Ore Fines | .

The process of sintering is basically a pretreatment process step during iron making to produce charge material called sinter for the blast furnace from iron ore fines and also from metallurgical wastes (collected dusts, sludge and mill scale etc.).

The Extraction Of Iron Chemistry LibreTexts

Descriptive Chemistry ... which are produced as a result of the steelmaking process. Wrought iron: ... processing and transporting the iron ore, ...

Different Types of Iron Ore Mineral .

Different Types of Iron Ore ... it may be workable by some concentrating process. ... We can IMPROVE ALL PLANTS / Mineral Processing Engineering LABORATORY Ore .

KOBELCO Pelletizing Process

KOBELCO Pelletizing Process ... method for processing taconite containing low grade iron ore. His process involved grinding taconite to

Iron Manufacturing process related to the specified ...

Sponge iron powder . The Höganäs process is a direct reduction method for production of sponge iron powder using magnetite ore (Fe3O4) and carbon as raw materials. The reduction process takes place in a gas fired tunnel kiln at around 1200°C for 60 hours producing a sponge iron cake that is crushed, milled and

Iron processing |

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting.

From ore to steel – ArcelorMittal

The steelmaking process starts with the processing of iron ore. The rock containing iron ore is ground and the ore is extracted using magnetic rollers. Finegrained iron ore is processed into coarsegrained clumps for use in the blast furnace.

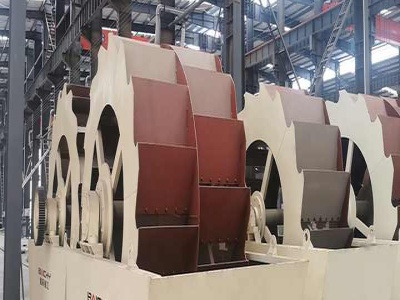

Iron Processing FEECO International Inc.

Our heavyduty iron ore balling drums are relied on by some of the industry's top producers to process iron ore fines into pellets for the steelmaking process. The use of a disc pelletizer is a

BBC GCSE Bitesize: Making iron

Making iron In the blast furnace ... The raw materials for extracting iron and their function in the process. ... Function; iron ore (haematite) iron oxide: a ...

How is Steel Produced? | World Coal Association

Global steel production is dependent on coal. 74% of the steel produced today uses ... During the ironmaking process, a blast furnace is fed with the iron ore, ...

SINTERING AND PELLETISATION OF INDIAN IRON ORES

SINTERING AND PELLETISATION OF INDIAN IRON ORES By ... ROM iron ore with Fe less than 58 ... Process objective is to transform fine iron ore concentrate

Processing plant | Roy Hill

Processing plant. The processing plant ... Beneficiation is the process of separating the valuable ... Lump ore produced from the processing plant will range in size ...

gcse 1. Introduction to the Extraction of Metals .

1. Introduction to the extraction of ... In extracting metals from ores you have to reverse the process by heating the ore ... Iron ore is used ...

Iron ore mining Schenck Process

Iron ore mining Working with Iron Ore industry to improve recovery. Schenck Process has been active in iron ore mining for more than 20 years by providing its special ...

Copper Mining and Extraction Sulfide Ores

Copper Mining and Extraction: Sulfide Ores. ... it is clear that iron and sulfur have to be removed in ... This flow diagram summarises the sulfide ore processing ...

Iron Ore and Pellets Vale

Vale is the world's leading producer of iron ore and ... Iron ore and pellets. Iron Ore ... is a long process. Learn the steps of iron ore production iron ...

iron and steel manufacturing | .

used by integrated steel plants that produce steel from iron ore. In this process, the iron ore is first subjected to a sintering process. Sintering Process is the technology for agglomeration of iron ore fines into useful 'Blast Furnace' burden material. • The treated iron from the sintering plant is fed in to the Blast furnace along with coke.

Latest Posts

- سحق وغربلة المنجنيز غانا

- كسارة الصخور المتنقلة على عجلة المسار

- آلة طحن الزركشة الزراعية

- مطاحن للقطع الجلود الطبيعية

- machine de transformation du cacao en poudre

- معدات سحق للبيع في السودان

- مصنع لإعادة التدوير الجبس وآلة طحن تكلفة

- مصنع هيكل الميكانيكية

- الجبس الصينية خط إنتاج معدات

- الاسمنت سحق آلة

- الشركة المصنعة لكسارة في اليابان

- الحصى كسارة تخطيط

- وحدة التكسير المتنقلة

- أعلى عرض كسارة jm1180 المهاجم

- حجر الكوارتز كسارة maomanry

- pebble mill cotic powder photo

- korea heavy submersible sand sludge pump

- jaw crusher producers in europe

- wet grinder 1 litre price in chennai

- how to make a handcrank for gold dry washer

- not attend the invitation letter sample

- jaw weightamp balance equipment

- mtc motorola com zenith bpmportal login jsp

- sand vashing mashineery

- cfbc boiler operation process in animation power plant

- Planta Trituración Cono

- mesin pemecah crusher digunakan untuk

- bauxite ore for sale at kolhapur

- bali stone supplier malaysia

- gold minin equipment