Clinker Grinding Speed

Clinker Grinders | Spec Ash Handling Plant

09/10/2009· The clinker grinder speed shall not exceed 40 rpm and the grinder drive motor speed shall not exceed 1000 rpm. The clinker grinders shall be provided with a reversing mechanism to reverse the direction of the .

Clinker grinding test in a laboratory ball mill using ...

Clinker grinding test in a laboratory ball mill using clinker burning with petcoke and coal 31 | Page mentioned in the literature (Gupta, Zouit and Hodouin, 1985; .

CONVENTIONAL CLINKER GRINDING A NEW .

CONVENTIONAL CLINKER GRINDING A NEW APPROACH TO THE PREDICTION OF POWER CONSUMPTION Tsakalakis School of .

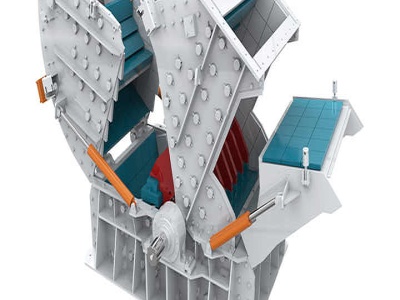

cone crusher clinker

Clinker crusher speed Cone Crusher for Clinker (Cement) – bulkonline Forums. babcock wilcox horizontal high speed pulverizers . best stone crusher manufactureing company ... clinker pre grinding hammer cone crusher . clinker crusher manufacturers in India Crusher South Africa .

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE .

production by cement clinker grinding. Production costs and environmental concerns are emphasizing the need to use less energy and require design updating in the ball mill components. For most of the twentieth century, the dry grinding circuits for the production of finished cement from cement clinker consist

LINKER ILICATE Silicate Crystal Size versus Kiln Speed in ...

changes in clinker microstructure as kiln speed increased. ... epoxy for cutting, grinding, and polishing. Through September 1999, the epoxy used was

pollution control system in clinker grinding

pollution control system in clinker grinding No Slide Title. ... We utilized technique of the basic—speed grinding and fine power coal collection with one machine.

Cutting speed — Klingspor

The selection of the optimum cutting speed during grinding depends primarily on the substance/material to be processed. For safety reasons, ...

clinker crusher speed – Grinding Mill China

Clinker grinder, lump breaker, grinding chamber measures 12" x 12", includes (13), Pelletizer is driven by 3 HP us varidrive thru adjustable speed reducer » Learn More. Cement Clinker Manufacturers. Cement Clinker Manufacturers, include CEMENT CLINKER, Cement clinker Grinding, highspeed hammer and materials, and the .

Clinker Ball Mill Clinker Ball Mill Manufacturer

sag mill critical speed grinding ... Cement Clinker Grinding Ball Mill Manufacturer Stone grinding plant Cement Clinker suppliers of Clinker Grinding Plant india, ...

Cement Mill,Cement Clinker Grinding Plant

Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media ... Rotating speed (r/min) Feed size ...

CLINKER AND GYPSUM GRINDING MILLS .

21/12/2016· manufacturing process for cement, clinker manufacturing plants, gypsum Home Cement Plants Clinker Grinding Clinker Grinding Unit In Baku: Ball Mill gypsum grinding areas gypsum grinding mill easily obtainedOmniBazar. Sep 20, 2014Barter, The grinding of the raw clinker to produce the finishedcourse, the cost,200mesh gypsum .

Clinker Grinder | Reduction Equipment for Scrap .

Clinker Grinder. The CG Series Clinker Grinder from American Pulverizer reduces clinkers ranging in feed size from 2" to 16" at temperatures up to 600 degrees F.

Clinker Speedboats | Home | Australian Register .

One of these is the racing speed boat ZOOM, a clinker hull with veed forward sections that gradually decrease in deadrise to the transom. ... Clinker Speedboats.

Quality Assurance of Cement from Production to Construction

Quality Assurance of Cement from Production . to Construction . Presented by : Choi 14. th . ... Formation of Clinker mineral Finish Grinding ... Tacho Speed Sensor

Cement clinker grinding: Evaluation of mill spin .

In this study, the milling of clinker was evaluated by varying the mill speed (24 and 72 RPM), residence time (3 and 5 hours) and grinding media load (30 and 40 %) in a ball mill. The experiment was designed as a three level factorial statistical model.

roller mill for cement clinker grinding in mexico

lowest energy consumption; best product quality with lower clinker ratio; zero water consumption a shell driven at supercritical speed; a roller applied on material ...

Cement kiln Wikipedia

heating the rawmix to sintering temperature (up to 1450 °C) in a cement kiln; grinding the resulting clinker to make cement ... Exhaust fan speed or power: ...

Used equipment For sale by Intercem 1 preowned clinker ...

1 preowned clinker grinding plant with ball mill ø 3,2m x 10,6 m ... box speed. / 52 rpm. 2. 1 Belt conveyor. Material: clinker / gypsum / additives.

Clinker Crusher Speed

fls rotary clinker crusher; clinker crusher speed; hammer clinker crusher spesification; crusher for cement clinker; ... Grinding Equipment. Ball Mill;

clinker crusher speed

Feb 15, 2016 Critical Speed Formula For Ball Mill formula for calculating the critical Cone Crusher critical speed of ball mill, Clinker Grinding Mill. critical

Factory Small Scale Equipment List Clinker .

Factory Small Scale Equipment List Clinker ... Find Complete Details about Factory Small Scale Equipment List Clinker Grinding ... is from the nozzle speed ...

ABB drives in cement Medium voltage drives for .

ABB drives in cement | 5 Cement grinding − Roller presses − Mills − Filters ... regulating the fan speed that draws cold air through the clinker

vertical mill speeds for clinker Mine Equipments

Cement Mill,Cement Clinker Grinding Plant Crusher Machine A cement mill is the equipment that used to grind the hard, nodular clinker from the ... Length), Rotating speed (r/min), Feed size (mm), Capacity (t/h), Grinding media load (t), Main motor, Main reducer, Weight(t) ... LM Vertical Grinding Mill ...

Efficiency of grinding stabilizers in cement .

The grinding stock formulation arose as a result of many years development of ultrafine cement clinker milling processes. The rotational speed of the mill chamber was maintained at a constant value of 66 min −1, The

Latest Posts

- آلة صنع طوب الطين العراقي

- مصنع الرمل في ولاية غوجارات

- محجر الركام المسحوق

- بيع مصنع كسارة في بربيل

- الاسبستوس المعدات محطم

- معالجات خام الكروم

- مصنعي معدات تكرير الحديد في مصر

- خطة عمل لأعمال كسارة المحاجر

- مطحنة طحن فحم الكوك المعدنية عالية الكفاءة

- pe250 مرات 400 كسارة الفك

- معيار 4 14 كسارة مخروطية دقيقة

- الرمال الشركات المصنعة محطم في أوما ن

- تصاميم مطحنة الكرة الشوكولاته

- مخطط nabard لكسارة الحجر

- شركات صناعة ايطاليا

- how to make difluoro calcium gt 97 from flourite ore

- Filter Crusher Single

- china mining equipment zenith branches list

- 3042 Cedarapids Jaw Crusher Repair Manual

- spare part toggle jaw crusher gulin 250 x 1000

- 1800w hd demolition breaker jack concrete hammer

- Ore Processing Concentration

- grinding methods cylindrical

- china piedras chancadora de impacto breaker

- machinery specification

- barite powder vietnam

- granite crusher picture

- wet grinding by stone discs

- Porcelain Jar For Mineral Grinding Coal Russian

- limestone blocks seconds perth