coal use in cement production process

LIFECYCLE ASSESSMENT AND EMISSION FACTOR .

LIFECYCLE ASSESSMENT AND EMISSION FACTOR ... process, and not to the production of coal ... and refine the fuels used in the cement manufacturing process ...

process coal in cement .

Types Of Coal Used For Cement Production In India. Coal for cement: Present and future trends Global Cement. ... semidry and dry cement, whereas the dry process ...

Utilization of Coal Combustion ByProducts and Green ...

Utilization of Coal Combustion ByProducts and Green Materials for Production of Hydraulic Cement 193 For instance, fly ash (a byproduct that largely ends up in ...

A feasibility study of using carbon black as a .

Cement factories traditionally use coal as an energy source in cement kilns since coal gives the high temperature that is required. Cement manufacturing is an energy intensive process. The extensive use of coal in kilns makes cement factories sensitive to rising prices of fossil fuels, and so an alternative fuel is needed to reduce fuel costs.

Cement, Coal Minerals | Thermo Fisher .

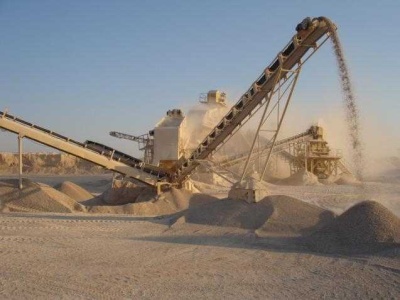

Cement, Coal Minerals. ... Cement Production Coal Mining ... Thermo Scientific™ crossbelt online analyzers for cement and coal reduce process upsets and increase ...

Use of coal as a fuel in cement plants and its impact on ...

still be used in cement kilns. Coal is a combustible carbonaceous rock, ... local coal, in cement manufacturing, ... With a wet process kiln

Energy Source for Cement Kilns: KIS .

The most modern plants in operation today which use the dry process and have precalcination ... There are few limitations on coal quality for cement production, some ...

Alternative Fuel Use in Cement Manufacturing

Alternative Fuel Use in Cement Manufacturing iii ... production Carbonintensive coal and petcoke are the most commonly used fuels, and

type of coal used in cement manufacturing – .

CEMENT PRODUCTION PROCESS AND TYPES manufacturer of filters for Various applications catering to Cement ... What kind of coal is used in cement production ...

coal use in cement production process nigeria

coal use in cement production process nigeria. We are the manufacturer of coal mining machine,roadheader,coal loader,tunnel mucking loader,backfilling machine,concerte pumping machine and so on. coal use in cement production process nigeria manufacturer, supplier.

type of coal used in cement manufacturing – .

What kind of coal is used in cement production. cement, types of coal used for cement production crusher used in cement manufacturing. » Learn More. types of coal used in steel plants. types of coal used in steel plants in india. type of coal used in cement manufacturing in india Solution for India Used Cement Plant Sale, Contact Details India.

Coal Use In Cement Production Process .

The use of the dry process for cement production has increased significantly in the last mixed with a greater quantity of lime to produce .

Thermal Energy Audit of Kiln System in a Cement Plant

for energy balance in industries. Cement industry is considered as an important energy intensive industry. Cement manufacturing uses dry process which includes the use of a rotary kiln, that consume large amount of energy to burn coal and the working of the blower which is used to suck the heated air to the other end of the rotary kiln.

Coal cement | World Coal Association

Coal is used as an energy source in cement production. Large amounts of energy are required to produce cement. It takes about 200 kg of coal to produce one tonne of cement and about 300400 kg of cement is needed to produce one cubic metre of concrete.

CRH Plc: Using Solid Recovered Fuel (SRF) as a .

... with the substitution of a proportion of the coal used at Platin Works ... from the cement manufacturing process. ... Business in the Community Ireland

Alternative Fuels in Cement Manufacturing | .

Alternative Fuels in Cement ... to consider briefly the cement production process. ... fuels such as coal and to be able to use them in cement ...

Alternative Fuels in Cement Manufacturing | .

Alternative Fuels in Cement Manufacturing ... fuel used in cement industry is coal. ... it is necessary to consider briefly the cement production process.

Alternative Fuels in Cement Manufacturing

Alternative Fuels in Cement Manufacturing 265 Cement production is an energyintensive process consuming thermal energy of the order of GJ/tonne of clinker ...

Latest Posts

- معدات تجهيز بناء الطرق الحجرية

- آلية العمل الكرة مطحنة

- مصانع الذهب إثراء باني الجزائر

- تأجير كسارة متنقلة في المملكة العربية السعودية

- كسارة مخروط محطم مع 400tph

- كسارة الشاشة

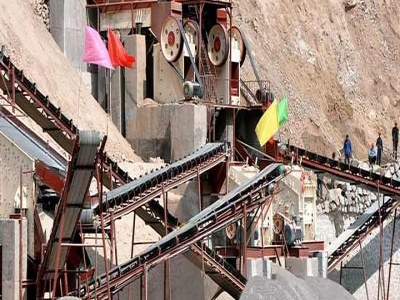

- مشروع كسارة كسارة الجرانيت

- لوم متناهية الصغر مطحنة الأسطوانة العمودية

- قائمة محطة كسارة المستخدمة في صناعة التعدين

- مصنع صنع الرمل الصناعي في الجزائر

- tph حجر محطم للايجار مصر

- مختلف شهادة مخروط محطم المحرز في عمان

- كسارة مطحنة الصخور في مصر

- كسارة الصخور الألمانية

- كسارة الفحم ل محطة كهرباء

- Indium Corporation Suzhou

- Zirconium Dioxide Systems

- komatsu crusher japan

- a700 east tyrolean grain mill

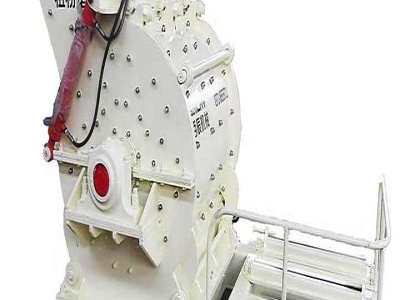

- construction of jaw crusher sbm

- Indium Iodine Machine

- design plans for screw screen conveyor

- Crusher Spares Pc1055j

- industrail corn grinder for sale

- site diagram for gold extraction

- silica sand north island new zealand

- capacity of gravel screening plants

- Pengumpan Apron Crusher

- 2012 mccloskey wheeled mounted stacker

- conveyor rollers saudi arabia