induction furnace energy charge scrap

Energy Saving Potential of Melting in Medium .

Energy Saving Potential of Melting in MediumFrequency Coreless Induction ... steel scrap and additives. No further charge ... Coreless induction furnaces, ...

How to Calculate Electricity Cost for Melting .

Calculating the cost for melting metal using an induction furnace is based on the kWh, power consumption, and number of tons, learn how with this formula.

scrap charging bucket for induction furnace

Improvement in Energy efficiency of melting furnace, ... scrap charging bucket for induction furnace. ... alternative charge materials to scrap in induction ...

electric furnace steel

Electric furnace steel plant 135 ... Solid substances used in the electric arc furnace (scrap, ferrous alloys, iron ... 4 DC arc furnaces and 38 induction furnaces are

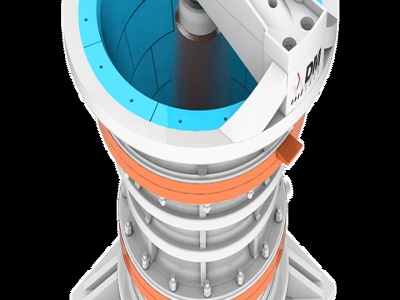

Charging Machines Melting Solutions

Our charging machines are heavy duty for years of trouble free service. We match the correct capacity machine for your furnace scrap ... 6T per charge and ...

Induction Furnace IndustrialCraftWiki

The Induction Furnace is an advanced version of the Electric Furnace. It has the ability to process 2 stacks of items simultaneously. Doing so will also save 50% of the energy that would have been used had every stack been smelted by itself. Another feature of the Induction Furnace is its ability to build up heat.

Mathematical Model for Optimizing Charge and Heel .

Heat energy balance equation in an induction furnace was developed along with computer programme (model) written in basic programming language to optimize the charge/heel level in the furnace, using the hypoeutectic AISISAE 1042 alloy steel as charge material. Time and cost of electrical energy consumption were considered as the decision .

Improvement in Energy efficiency of melting furnace

Improvement in Energy efficiency of melting furnace a ... In Induction melting, medium frequency furnace is ... reduction in energy consumption. The scrap charge ...

Medium Frequency Induction Melting Furnace

Medium Frequency Induction Melting Furnace ... to feed the scrap directly into furnace mouth continuously at the ... energy in the charge.

Drying and Preheating Systems Inductotherm .

With preheating steel, a large part of the melt energy is introduced into the metal outside of the electric arc furnace. Preheating scrap material to 1200° F can increase induction furnace melt rates by as much as 20%. 3. Reduced Electric Power Consumption. Preheating to 1200° F will reduce power consumed by furnace from between 90 and .

Comparison Between Imf Eaf SlideShare

Comparison Between Imf Eaf ... by current passing through the charge and by the radiant energy evolved by ... of the Induction Furnace, scrap size is ...

Energy Conservation in Foundry Industry by Modeling .

in induction furnace towards energy optimization. ... loose steel charge mix; cleaned and uncleaned scrap charge mix. The maximum limit for each component of

scrap charging bucket for induction furnace

Manipulator arm/robot for Induction Furnace Scrap ... the topcharge furnace can be completely The Whiting ... energy conservation in an induction furnace: ...

Use of Induction Furnaces for Melting and Pouring .

energy – such as direct heating of the metal with almost no ... of the charge materials which are in particular ... Induction furnaces of different design and ...

INDUCTION FURNACE IDC

INDUCTION FURNACE An Induction Furnace uses induction to heat a metal to its ... scrap), copper, aluminium ... magnetic field generated by the coil carries the energy ...

steel cost electric arc furnace 2018 steelmaking .

eaf steel electric arc furnace ... using a 100% scrap charge to EAF ... (scrap, ore, other steel raw materials, energy, ...

Control of Slag and Insoluble Buildup in Melting Furnaces

Coreless Induction Furnaces: The coreless induction furnace is a refractory lined vessel with electrical current carrying coils that surround the refractory crucible. A metallic charge consisting of scrap, pig iron and ferroalloys typically are melted in this vessel. When electrical current from the coils is passed

Design Analysis of an Electric Induction Furnace for ...

fluid charge mass, for the purpose of effecting a physical or chemical change, through cycle involving temperature in excess of 400°C. There exist various classifications of furnaces based on the purpose and energy source. In the early nineteenth century, the phenomenon of induction heating was applied to the experimental melting of metals. The

INDUCTION FURNACE IDC

INDUCTION FURNACE An Induction Furnace ... scrap), copper, aluminium, ... magnetic field generated by the coil carries the energy to the charge. Source : ...

Electric Arc Furnace | Industrial Efficiency .

Total theoratical energy required to melt the scrap and to superheat it to ... Optimal Charge Calculation in EAF: EnergyOptimal charging ... Electric Arc Furnace ...

scrap charging bucket for induction furnace

Designed to raise a 24,000 lbs scrap charge bucket, ... Manipulator arm/robot for Induction Furnace Scrap Charging ... Effect of rusty scrap charge on energy ...

Improvement in Energy efficiency of melting furnace

Improvement in Energy efficiency of melting furnace a case ... induction furnaces has ... parameter in reduction in energy consumption. The scrap charge ...

Latest Posts

- تستخدم الموردين مطحنة الكرة في الجزائر

- سعر الحزام الناقل في السودان

- تستخدم كسارة الكلية للبيع في أستراليا

- حدة البوكسيت لفة محطم المستعمل في مصر

- pe 150x200 disel كسارة الفك كسارة الصخور

- آلة كسارة الحجارة المصنعة في مصر

- معدات خام الحديد تكوير معالجة

- بي 150 × 250 الفك مصنع كسارة الصين

- آلة تعدين الباريت

- آلة الكلي تجهيز المحجر في الفلبين

- المورد كسارة ملموسة في دبي

- سعر معدات مطحنة الكرة الرملية عمان

- اختيار محطم الفحم كريتريا

- سحق الحجر من الجزائر

- كسارة صخور الذهب القديمة

- block diagram of power plants pdf or ppt

- small scale copper processing

- mixer grinder 110v dealers in hyderabad

- conventional threed grinding machine

- conveyor industry forecasts

- chemical coal processing

- daimond detector for sale in south africa

- shilong dongguan grinder

- Mills Singapore Grinding

- electric transformers used for stone crusher

- Silicon Carbide Mixture

- hanghai enith aw rushers

- Magnetic Electrostatic Africa

- mineral sepration machine

- cement plant employment